Why Smart ?

Smart Vietnam R&D Ability

Smart Vietnam R&D Ability

The ideas take shape and are developed here, thanks to the joint efforts of a team of highly specialized technicians and engineers

Research is essential for efficient molds

The quality of a product depends on the quality of the design: a long process that is comprised of studies and continuous checks, successes and failures. Each question mark becomes a challenge to improve, exploring new paths and experimenting ever-changing technological solutions, with the objective of providing a secure and reliable response every time.

The R&D department is the brain of the company. The ideas take shape and are developed here, thanks to the joint efforts of a team of highly specialized technicians and engineers, through an open dialog with other operators in the sector and with the academic world.

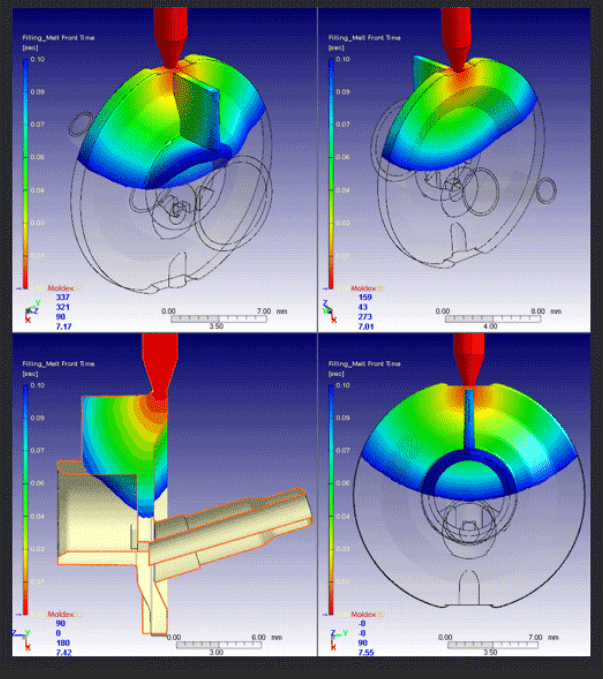

Perfection is experience and technology

We use cutting edge design and simulation technologies. Moldex3D is the world leading CAE product for the plastics injection molding industry. With best-in-class analysis technology, Moldex3D helps us perform an in-depth simulation of the widest range of injection molding processes to optimize product design and manufacturability. Furthermore, the instantaneous connection to our CAD systems generates a flexible simulation-based design platform.

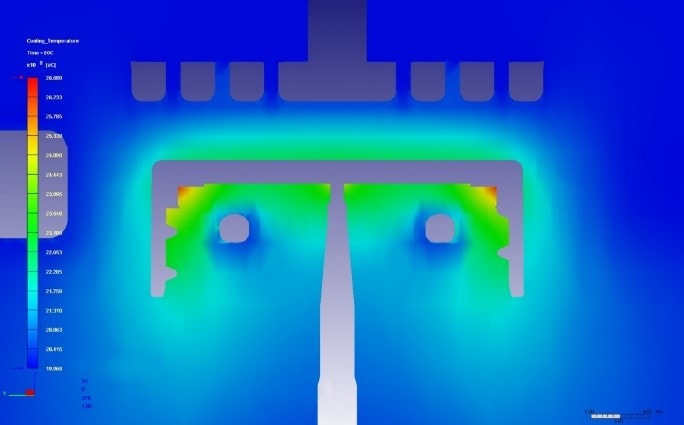

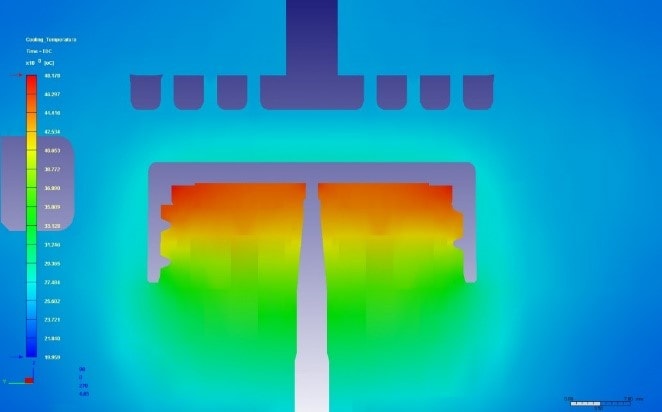

The videos show the cooling process for molded parts with conformal channels (the blue part represents the water circuit).

Traditional and advanced technology

The two images show the considerable difference in cooling obtained when the mold has conformal channels (second image: better cooling) in comparison to those without them, as they were created using traditional technology. In the first image, cooling is less complete.